In CNC machining, many features may look straightforward in a design, but they can significantly impact manufacturability. In some cases, these design choices drive up cost, extend lead times, or make a part impractical to produce. Understanding these issues early can be the difference between a fast quote and repeated design revisions.

At Approved Machining, our goal is to help customers save time and money on every project. Below, we outline eight of the most common design mistakes we encounter and share practical ways to avoid them.

Table of Contents

- 1 1. Insufficient Drill Depth

- 2 2. Square Corners in Pockets

- 3 3. Raised Text Instead of Engraved Text

- 4 4. Excessively Thin Walls

- 5

- 6 5. Draft Angles Designed for Molds

- 7 6. Deep Features Near Walls

- 8 7. Small Radii in Deep Pockets

- 9 8. Radiused Areas That Require Blending

- 10 Communicate With Us Early to Ensure Your Success

- 11 Design CNC Parts FAQ

- 11.0.1 What is the most common CNC machining design mistake that increases cost?

- 11.0.2 Why do thin walls cause problems in CNC machining?

- 11.0.3 Why are square corners in pockets difficult to machine?

- 11.0.4 When should draft angles be included in a CNC machined part?

- 11.0.5 How early should I involve my machine shop in the design process?

1. Insufficient Drill Depth

When a tapped hole depth matches the drilled hole depth, chips have no space to evacuate. As chips compact at the bottom of the hole, they can break the tap and scrap the part. To prevent this, the drilled hole should extend beyond the required thread depth. For example, if you require 0.5 inches of threads, the drilled hole should extend approximately 0.050 inches deeper.

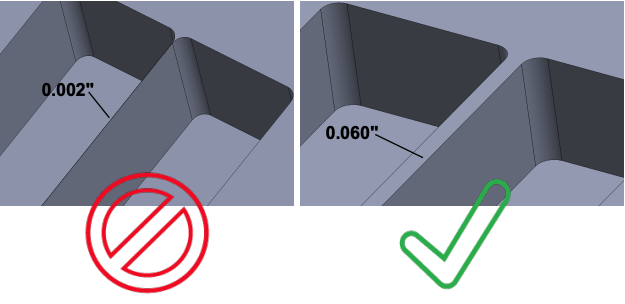

2. Square Corners in Pockets

CNC machines use round cutting tools, which makes perfectly square internal corners impossible to achieve with standard machining processes. In most cases, adding a radius to pockets or cutouts has little to no impact on part function or assembly. While processes such as EDM can create square corners, they significantly increase cost and lead time compared to standard CNC milling.

3. Raised Text Instead of Engraved Text

Raised or embossed text may look appealing, but it adds machining time and cost, particularly for small lettering. Tool radius limitations also require corner radii that can distort letter shapes and reduce readability. Engraved text is faster to machine, more durable, and typically easier to read, making it a better choice for most applications.

4. Excessively Thin Walls

Walls thinner than 1/8 inch are more susceptible to chatter, where vibration occurs during cutting. This can result in poor surface finish, dimensional inaccuracies, or part failure. Thin walls are also more likely to warp or sustain damage during handling. When possible, increasing wall thickness improves rigidity, machining stability, and overall part quality while reducing cost.

5. Draft Angles Designed for Molds

When machining prototypes intended for eventual injection molding, engineers often include draft angles required for molded parts. In CNC machining, these angles can complicate toolpaths, require specialty tooling, and increase cost. Unless draft angles serve a functional purpose in the prototype, they are typically best removed during the machining phase and reintroduced later for mold design.

6. Deep Features Near Walls

Deep features such as holes placed close to internal walls can create tool clearance issues. Cutting tools need sufficient space to reach depth without contacting adjacent walls or damaging tooling. Adjusting feature location to allow for proper clearance helps reduce machining risk and improves consistency.

7. Small Radii in Deep Pockets

When designing deep pockets with small corner radii, it is important to consider the length-to-diameter ratio of the cutting tool. A common guideline is to avoid cut depths greater than eight times the tool diameter. Exceeding this ratio increases the risk of tool breakage, poor surface finish, and longer cycle times. Increasing corner radii makes parts easier and more cost-effective to machine.

8. Radiused Areas That Require Blending

Intersecting radiused surfaces, especially around pocket walls or external features, often require blending during machining. Due to process limitations, the finished appearance may differ slightly from the CAD model. If surface appearance is critical, it is best to discuss acceptable solutions early in the design process.

Communicate With Us Early to Ensure Your Success

While many challenging features can be machined, they often come with higher cost and longer lead times. Communicating with your machine shop early and remaining open to design adjustments can result in faster quoting, smoother production, and more cost-effective outcomes without sacrificing functionality.

Request a quote from Approved Machining today to start collaborating on your next project.