At Approved Machining, we deliver precision-machined parts across a range of materials, from steel to plastic. With our industry experience and expertise, we achieve exceptional tolerances on every project, even when working with demanding materials.

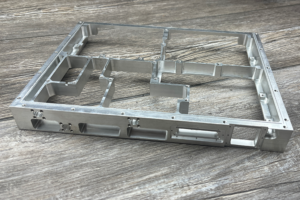

Among all the materials we machine, aluminum stands out as the most popular choice for our customers. This versatile metal offers an excellent strength-to-weight ratio, strong machinability, and cost efficiency, making it well suited for applications across a wide range of industries. Our machinists’ decades of experience working with aluminum allow us to deliver parts quickly and accurately.

Learn the advantages of aluminum and how our expertise with this material benefits our customers.

Table of Contents

- 1 Why Aluminum? Key Benefits for CNC Machined Parts

- 2 The Most Requested Aluminum Alloys at Approved Machining

- 3 Why Our Aluminum Expertise Improves Your Bottom Line

- 4 Aluminum Machined Part Design FAQ

- 4.0.1 Why is aluminum the most commonly used material in CNC machining?

- 4.0.2 Which aluminum alloy is best for CNC machining?

- 4.0.3 Is aluminum suitable for tight-tolerance CNC machined parts?

- 4.0.4 How does aluminum compare to steel or stainless steel in machining cost?

- 4.0.5 When should aluminum not be used for CNC machining?

Why Aluminum? Key Benefits for CNC Machined Parts

When evaluating materials, understanding the advantages of each option helps determine the best choice for a given application. Engineers often select aluminum for CNC machining due to several key benefits:

- Strength-to-weight ratio: Aluminum’s low density enables lightweight parts without sacrificing performance. This is especially important in industries such as aerospace and automotive, where reducing weight directly impacts efficiency.

- Corrosion resistance: Many aluminum alloys provide natural corrosion resistance, making them suitable for a variety of outdoor and industrial environments. Aluminum is also compatible with surface finishes that further enhance corrosion protection.

- Thermal properties: Aluminum offers excellent thermal conductivity and is commonly used in applications such as heat sinks. Its dimensional stability across a wide temperature range makes it reliable in demanding operating conditions.

- Cost-effectiveness: Although aluminum’s raw material cost can exceed that of options like carbon steel, its availability in multiple grades and forms often results in lower total production costs. Faster precision machining speeds with aluminum can further reduce overall expense.

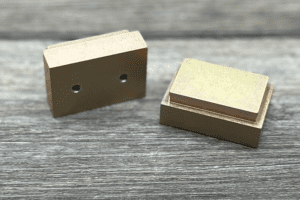

Aluminum’s machinability and cost efficiency support a wide range of use cases. In some projects, designers may specify more expensive metals for final production, while aluminum serves as an ideal prototype material for testing fit and function. Aluminum is also frequently used for display or demonstration parts, such as trade show components, where it delivers strong aesthetics without the cost of premium materials.

Despite its versatility, aluminum is not always the best choice. For example, steel may be better suited for parts with extremely thin walls, as aluminum can be more prone to warping or distortion in these situations.

The Most Requested Aluminum Alloys at Approved Machining

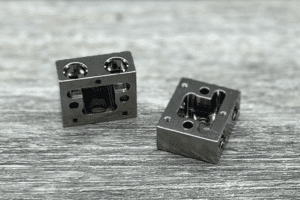

There are important differences between aluminum alloys, and selecting the right grade depends on performance requirements and application needs. Some of the most common alloys we machine include:

6061: This alloy combines magnesium and silicon to provide balanced strength, corrosion resistance, and machinability. Its widespread availability and consistent performance make it our most frequently requested aluminum grade.

7050/7075: These zinc-based alloys are commonly used in high-performance applications such as aerospace. They offer higher strength than 6061, though typically at a higher material and machining cost.

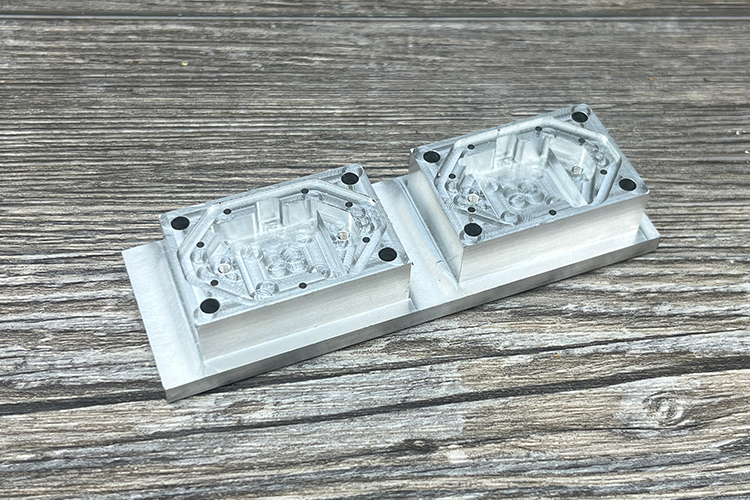

MIC-6: This cast aluminum tooling plate is well suited for parts that require superior flatness, especially when machined at stock thickness. MIC-6 should be avoided in vibration-prone applications due to the risk of cracking.

Why Our Aluminum Expertise Improves Your Bottom Line

Aluminum’s superior machinability translates directly into customer value. Based on our experience, carbon steel generally takes about 1.5 times longer to mill than aluminum, while stainless steel can take up to twice as long.

These time differences become more significant as production quantities increase. While setup and programming costs are spread across the entire run, machining time applies to every part. Faster aluminum machining speeds therefore have a greater impact on unit cost as volumes grow.

Our established network of finishing partners complements our in-house machining capabilities, providing complete surface treatment options for aluminum parts. Whether your project requires anodizing, chromate, powder coating, or electroless nickel plating, our vetted vendors deliver consistent quality with reliable turnaround times. This approach allows you to source precisely machined and professionally finished parts from a single supplier.

Do you need CNC machining services for your next aluminum part? Request a quote today.